First I have to say that I am very tired of grey and rain. Very. Tired.

I am aware that it’s only January, and that this will be with us here on the Oregon Coast for many moons yet…just like it was in Bellingham. But being home during the day definitely colors the…well…grey. Sigh.

Anyhow, I had intended to sample and swatch two down-type breeds from my breed study box for this post. I did the Southdown, and then went for the Suffolk. Which was, quite unexpectedly, GREY.

Now, I’m pretty new to the spinning world, but I’ve learned enough to know that the down-type breeds are primarily meat sheep – fleeces are an afterthought. Down-type herds in the United States are almost exclusively white (many with black faces) so that their fleeces can be sold into the wool pool for industrial or mass market wool items. (Fun fact – Pendleton purchases the vast majority of the wool pool in the US.) Wool pool wool needs to be white so it can be dyed any color the purchaser wants…non-white lambs are usually culled from herds. So this little fluff of grey wool labeled “Suffolk” was perplexing.

What to do? Consult the Fleece and Fiber Sourcebook, of course. Sure enough, there is a little note in it about a grey mystery wool being sold as grey Suffolk…that bears absolutely no resemblance to regular Suffolk. So, back into the box it goes. Perhaps I’ll spin it at some point, but it doesn’t help my study very much right now!

Southdown

So, on to the Southdown. Southdown is the grand-pappy of all the down-type breeds, so it was an obvious starting point with down-type wool. In reality it was just the poof of fiber I pulled from the box, but…never mind that.

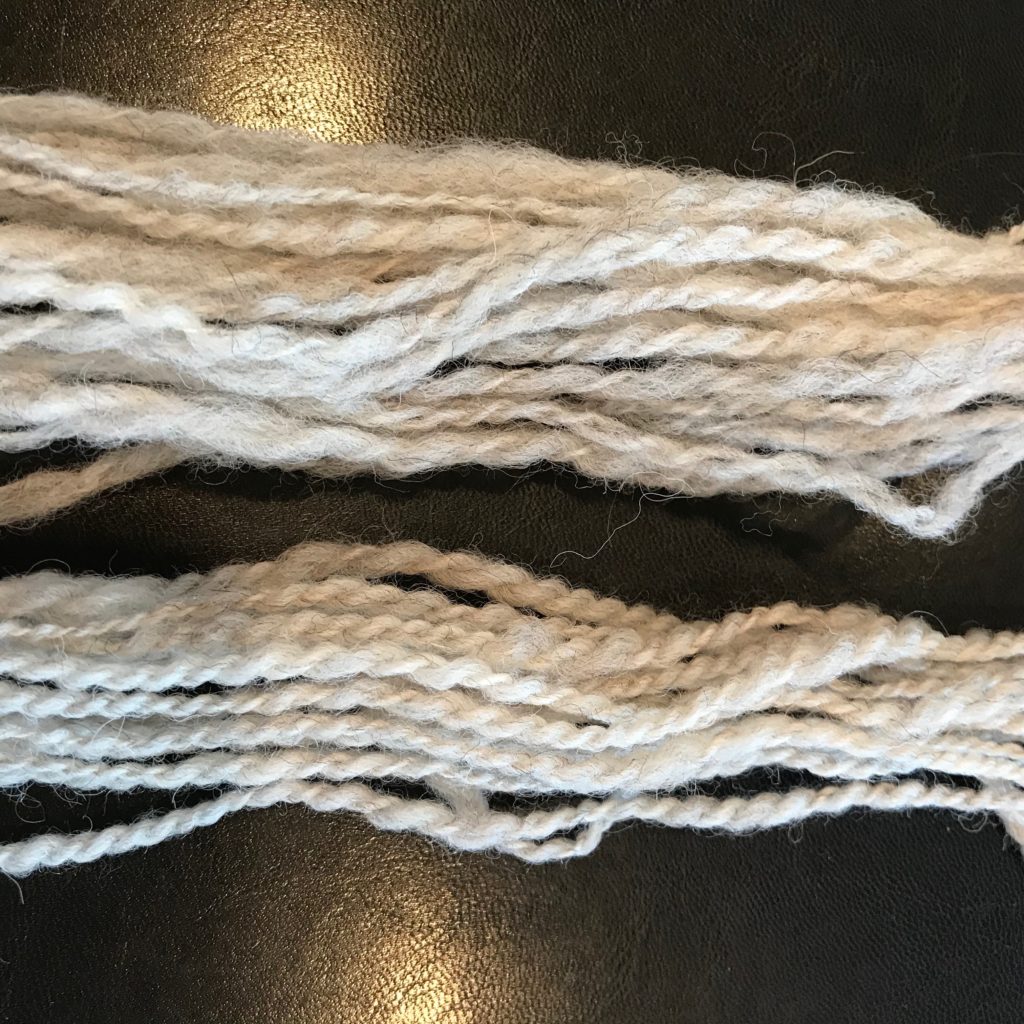

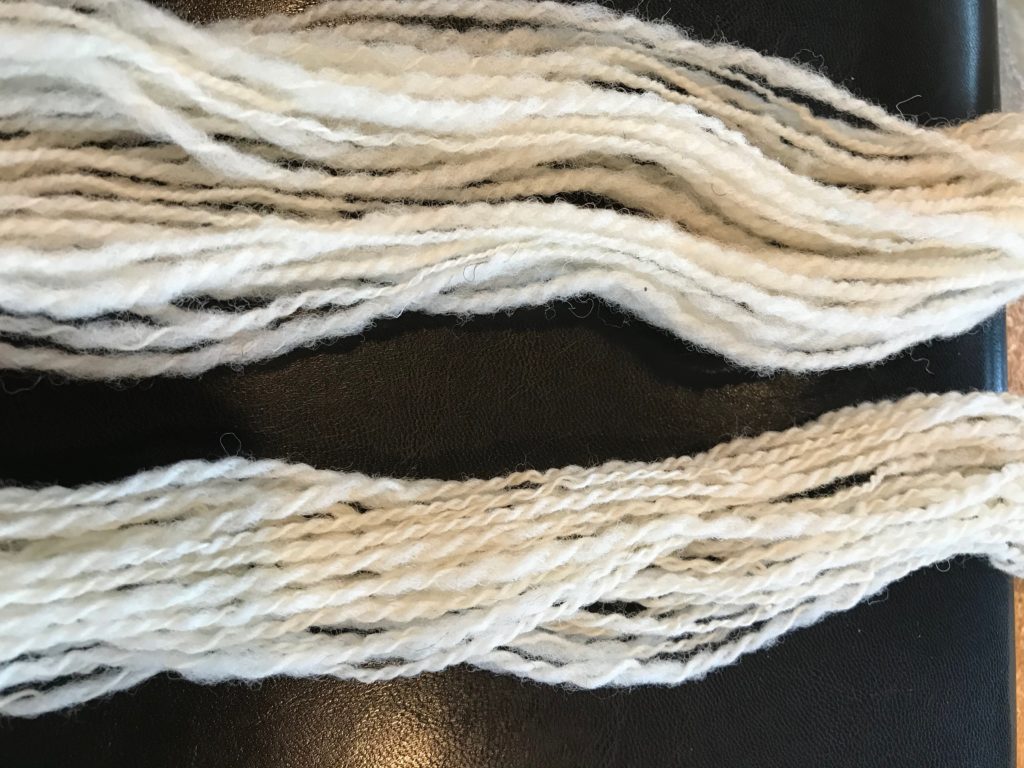

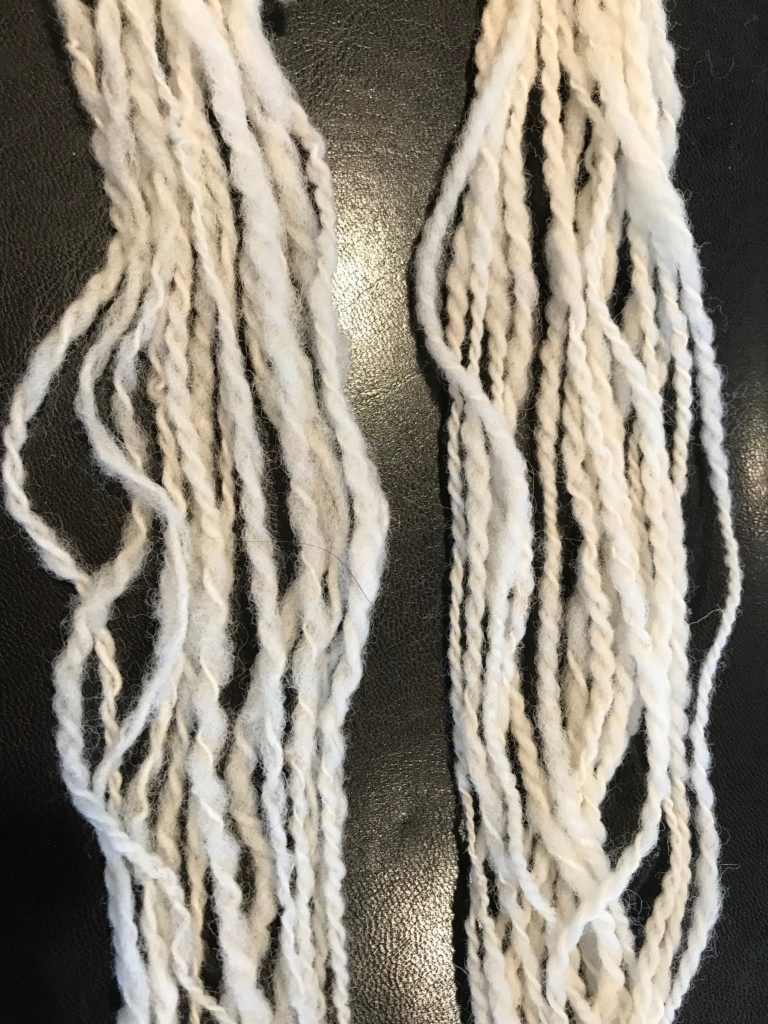

As always, I spun half of my one ounce sample worsted style and half woollen. I keep looking at my samples and thinking that they don’t look that different, for the most part. My consistency wasn’t great in either case, apparently, and the thick and thin bits are pretty obvious in both sample skeins. I am still working on getting enough (but not too much) twist into my long draw singles so they don’t fall apart during plying, and this time I only had a couple of breaks! I’m going to consider that a win.

The result of one of the breaks was two plying bracelets. Why two? Because one of the traits of a down-type breed is that the wool will not felt, so my usual spit-splice method of disguising breaks in my singles wasn’t an option. Two bracelets it was. Which, as it turned out, was perfect for sampling.

I started my plying with 4 treadles per 12-15 inches on my 8:1 ratio. Straight off the bobbin it was a little under-plyed, so I upped my treadling on the larger bracelet to 5 per 12-15 inches on the same ratio in an attempt to balance it – only to discover that then it was slightly over-plyed. I washed them and blocked them and didn’t see a lot of difference, but the real difference was in the swatches.

The worsted yarn is denser and the stitch definition is cleaner (mostly), which is to be expected. I like the nubbles where I was inconsistent in my spinning, and I think this would make quite a nice sweater that would be durable and long-lasting. It would also make lovely socks, I’m pretty sure.

The woollen spun swatches are the interesting part. Although I liked the look of the more tightly plyed yarn better, I like the knitted swatch that uses the under-plyed yarn better. It more closely resembles what I’ve been taught a woollen-spun yarn should be – light, airy, and fuzzy. Although I don’t know how well it would hold up to significant wear, I really love how the swatch feels now. An under-plyed laceweight Southdown yarn might be quite lovely and I suspect it would bloom nicely over time.

I would absolutely experiment with Southdown again. And since my husband thinks that Babydoll Southdowns should be part of our future fiber herd, I guess that’s a good thing!